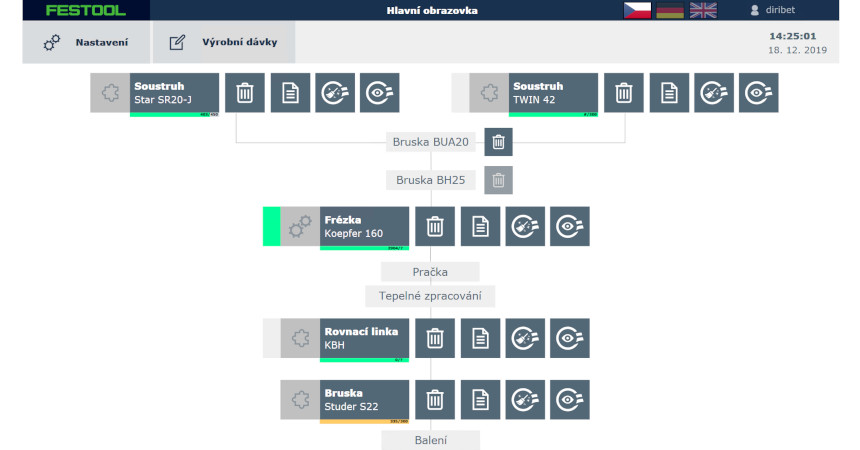

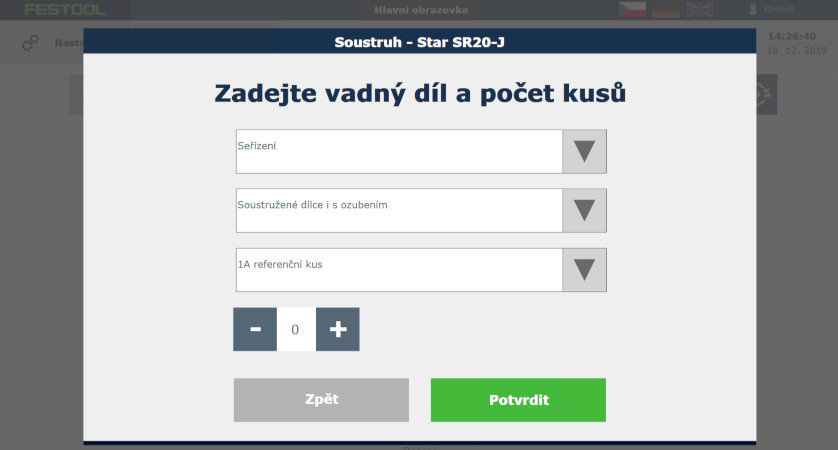

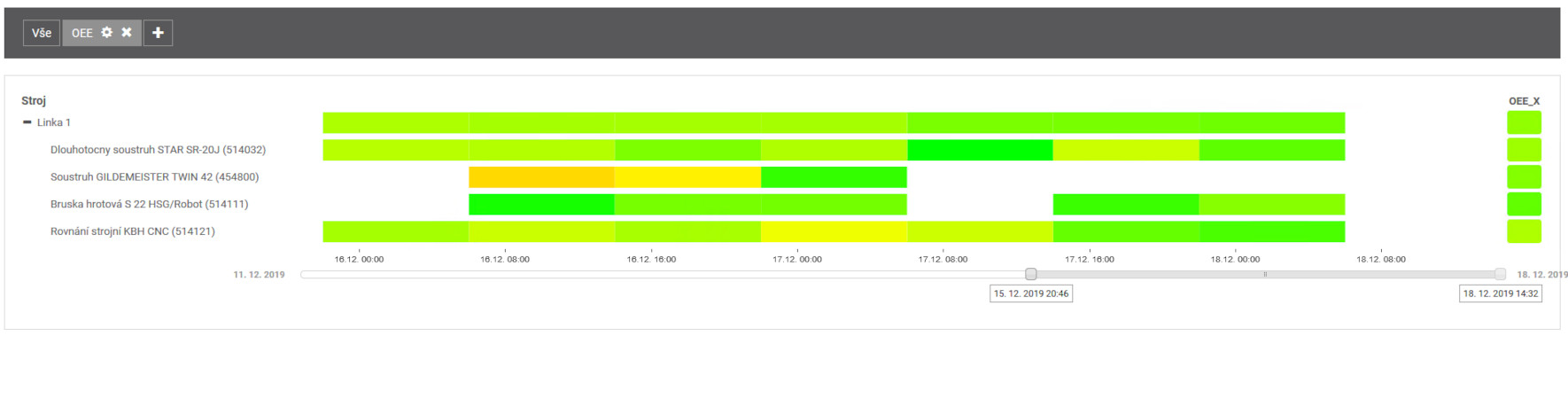

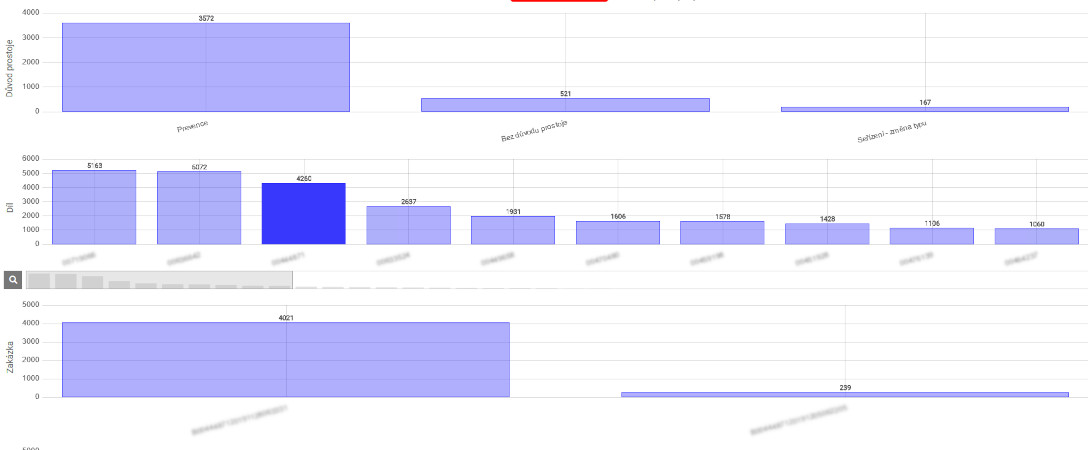

A project in the Festool company, which is the manufacturer of hand tools. Our solution is used in the production line of shafts that are mounted in cordless screwdrivers. The core of the solution is the collection and visualization of data from production machines (PLC) and measuring systems, interactive (HMI) terminals for production operators and ensuring communication between the production and measurement centre. The main benefit of the solution is transparent information about machine availability, quality and productivity, from which we are able to adequately calculate OEE of the line. ..and what was the most successful?

-

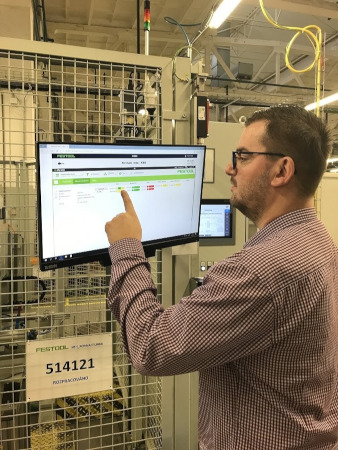

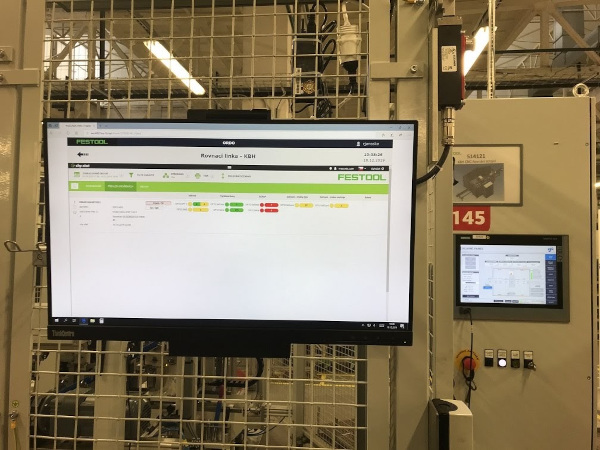

Monitor

Transparent monitoring of availability, productivity and production quality. Effective and rapid interventions in the production process to ensure maximum OEE of the line. In addition users can see overviews of all machine statuses, manufactured parts and measurements. Monitoring is the right tool for operative support of decision-making of production line masters and adjusters who intervene in the production process. -

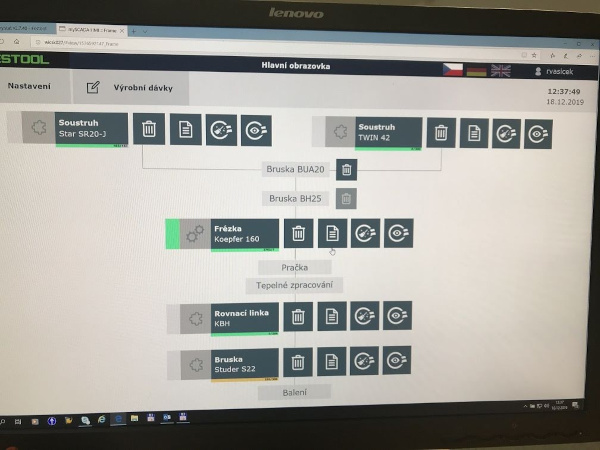

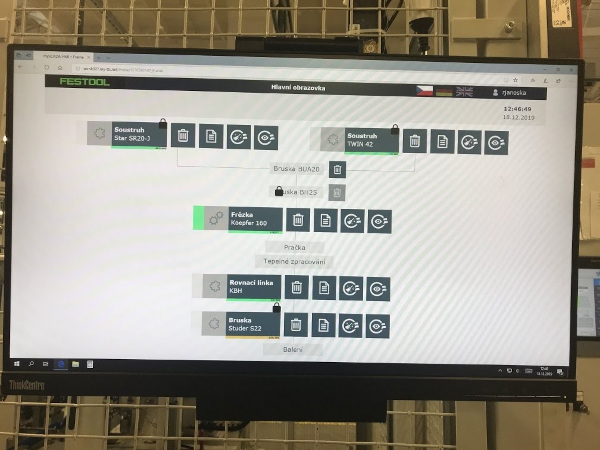

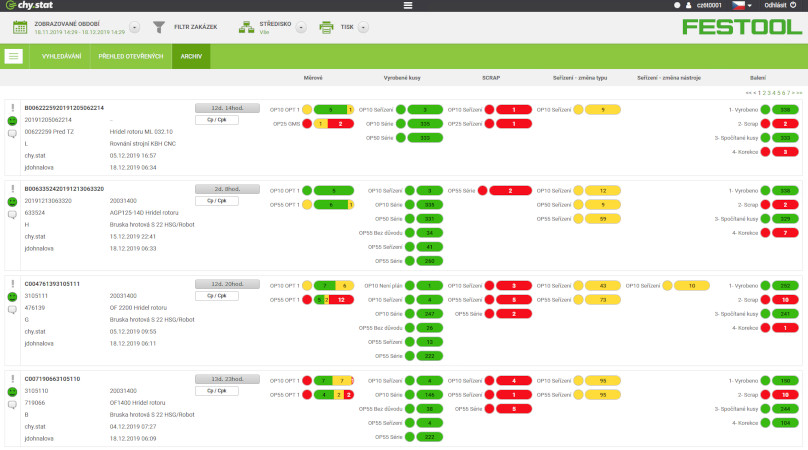

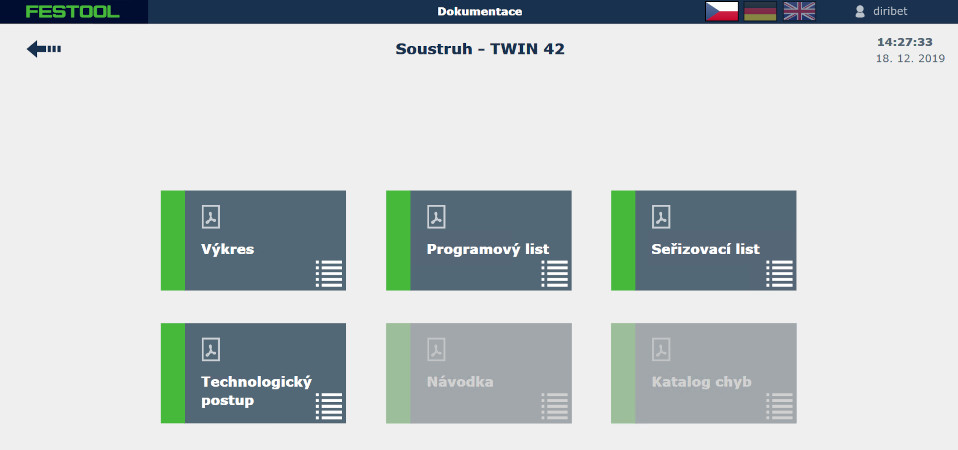

Ordo

All production and quality information about the whole production order in one place. The user can easily display current information about the production order or trace any completed production order. Another benefit is the monitoring of the number of pieces produced per order.